Products

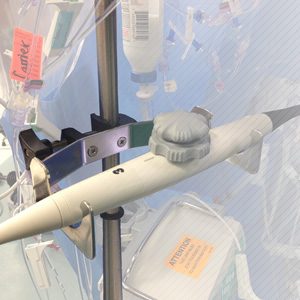

Device Disinfection

Device Care & Storage

21

Years of Experience

3 or 5

Minute Disinfection Time

8

Over Eight Million

High-Level Disinfections

High-Level Disinfections

0

FDA Medical Device Reports

Schedule a time to speak with one of our sales professionals

Request a Product Price Quote today